Riverstone Machining LLC

Fabrication

Building upon our core expertise in precision machining, Riverstone Machining LLC has made a significant investment in our fabrication capabilities. This strategic expansion allows us to provide a more comprehensive solution to our clients, taking projects from raw material to finished product all under one roof. Our state-of-the-art fabrication department is equipped with the latest technology, ensuring the highest standards of quality and efficiency.

At the heart of our fabrication operations is a new 16,000-watt laser with full automation. This cutting-edge machine provides unparalleled speed and precision, capable of cutting a wide range of materials up to one inch thick with exceptional accuracy. With cutting speeds up to 1,000 inches per minute, this technology enables us to handle high-volume production runs and complex geometries with ease, significantly reducing lead times and ensuring consistent, repeatable results for every part we produce.

To complement our laser cutting capabilities, we have also integrated advanced forming technology. Our two new Amada brake presses, with bending capacities of 140 and 240 tons, allow us to precisely form and shape a variety of metal sheets. This combination of high-speed laser cutting and powerful, accurate forming gives us the versatility to produce intricate parts and complex assemblies, offering a seamless and efficient process for our customers' fabrication needs. From simple brackets to complex enclosures, our fabrication services are designed to meet the most demanding specifications with a focus on quality, speed, and competitive pricing.

Riverstone Machining: Precision Crafted, Performance Delivered

Why Choose Us

Riverstone Machining is the ideal choice for anyone seeking precision machining services. With years of experience and a team of highly skilled professionals, Riverstone Machining consistently delivers top-quality products that meet the most stringent standards. Our state-of-the-art facility is equipped with advanced machinery and cutting-edge technology, enabling us to handle complex projects with utmost efficiency. We turn your vision into a reality!

Headline Goes Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Headline Goes Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Headline Goes Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Headline Goes Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Headline Goes Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Headline Goes Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit

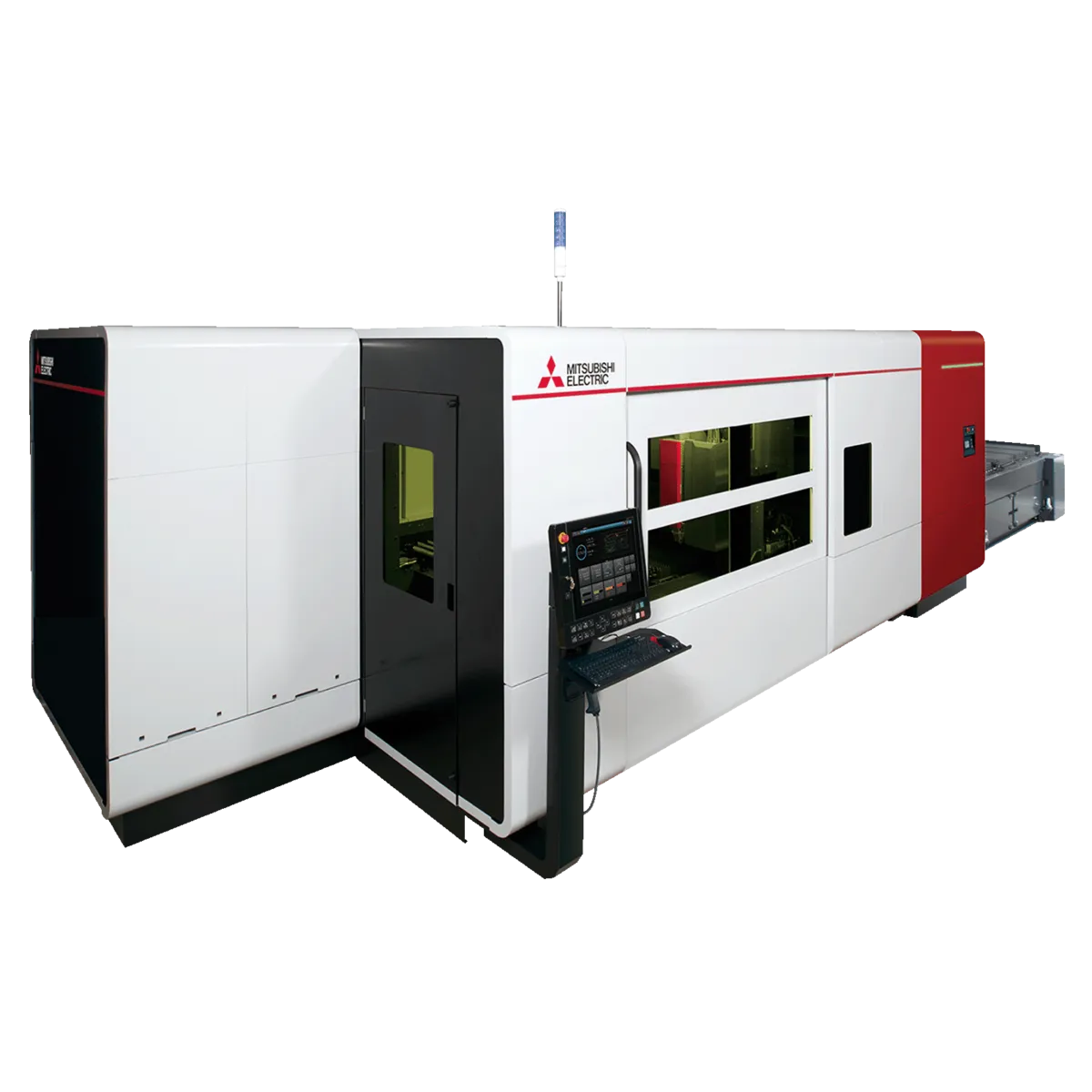

MITSUBISHI GX-F LASER

16,000 WATT LASER CUTTING SYSTEM WITH AUTOMATION

The Mitsubishi GX-F ADVANCED Series is a two-dimensional fiber laser that uses advanced AI and assist-gas technologies to deliver powerful, efficient, and precise cutting.

- Versatile Cutting: 16,000 watts allows for cutting speeds up to 1,000”/min. We can precisely cut steel, stainless and aluminum from 18ga up to 1” thick.

- Intelligent Automation: Built-in AI and augmented reality (AR) features simplify operation, reduce setup time, and automatically optimize cutting parameters and speeds in real time. The machine even automatically replaces defective nozzles for continuous processing.

- Reduced Gas Consumption: Mitsubishi’s proprietary AGR-MIX nozzle technology improves cut quality while significantly reducing nitrogen and other assist-gas consumption by blending it with low-pressure air, lowering operating costs.

- Advanced Capabilities: A zoom cutting head adjusts the beam for different materials and thicknesses, reducing piercing time by up to 60%. The M800 user interface with a 19-inch touchscreen provides intuitive, smartphone-like controls.

- 8 Shelf Automated Tower System: SmartFlex Rapid Tower has 5,000 lb capacity shelves which auto load/unload for continuous “lights out” operation.

- Nesting Software: CAD/CAM process that optimizes placement of multiple parts on a single sheet of material to minimize waste and improve material utilization.

AMADA EGB 1303 ATC PRESS BRAKE

The Amada 1303 ATC Press Brake is equipped 143 tons and a 122” bed length.

Benefits of having an Automatic Tool Changer:

- Load the most complex tool setups within minutes

- Ideal solution for variable lot sizes and seamless introduction of rush jobs

- Operators of all experience levels can efficiently set up bend programs within minutes

- Tools are loaded from tool magazine more efficiently than conventional tool changes.

AMADA HG 2004 PRESS BRAKE

The AMADA HG 2204-M15 is a high-capacity, servo-hydraulic press brake from the HG series, designed for high-speed, accurate bending of various sheet metal thicknesses.

- High tonnage: The HG 2204 press brake offers 220 tons of bending capacity.

- Long bend length: It provides a generous bending length of 4,300 mm (169.3 inches), allowing for multi-stage bending and the creation of long parts.

Headline Goes Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor

incididunt ut labore et dolore magna aliqua.

Headed Goes Here

Lorem ipsum dolor sit amet, adipiscing elit,

sed do eiusmod incididunt ut incididunt

labore et dolore.

Headline Statement

Lorem ipsum dolor sit amet, adipiscing elit,

sed do eiusmod incididunt ut incididunt

labore et dolore.

Another Headline

Lorem ipsum dolor sit amet, adipiscing elit,

sed do eiusmod incididunt ut incididunt

labore et dolore.

Headline Statement

Lorem ipsum dolor sit amet, adipiscing elit,

sed do eiusmod incididunt ut incididunt

labore et dolore.

More Headlines Here

Lorem ipsum dolor sit amet, adipiscing elit,

sed do eiusmod incididunt ut incididunt

labore et dolore.

Additional Headline Here

Lorem ipsum dolor sit amet, adipiscing elit,

sed do eiusmod incididunt ut incididunt

labore et dolore.

About Us

Our History

Riverstone Machining LLC is a family-owned technical contract manufacturer of precision machined components located in Fox Lake, Wisconsin. In 2010, Integrity Machine Corporation, who had a long-standing reputation of offering quality parts to customers throughout southeastern Wisconsin since 1995, was purchased and became part of the Riverstone family.

In November of 2019, the assets of Metal Solutions, Inc in Sun Prairie, WI were acquired and, within two years, construction on a 30,000 sq ft addition began on the Fox Lake property. The new manufacturing and office areas were unveiled in 2023, bringing our total square footage to 60,000. The Sun Prairie operation was then moved to Fox Lake to house all production operations under one roof.

Riverstone Machining LLC currently employs thirty-five people working two shifts daily. We provide a wide range of precision computer numerical control (CNC) machining and are equipped with the latest and most technically advanced equipment. This technology, coupled with decades of manufacturing experience, allows us the capability to meet any custom, production, turning and milling needs. We are committed to deliver competitively-priced, quality parts when you need them.

Our Staff

Meet Our Team

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor

incididunt ut labore et dolore magna aliqua.

Jane Doe

Title Goes Here

John Doe

Title Goes Here

Jane Doe

Title Goes Here

Frequently Asked Questions

Your Title Here

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Autem dolore, alias, numquam enim ab voluptate id quam harum ducimus cupiditate similique quisquam et deserunt, recusandae.

Your Title Here

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Autem dolore, alias, numquam enim ab voluptate id quam harum ducimus cupiditate similique quisquam et deserunt, recusandae.

Your Title Here

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Autem dolore, alias, numquam enim ab voluptate id quam harum ducimus cupiditate similique quisquam et deserunt, recusandae.

Hours & Location

Business Hours

Mon – Fri: 7:30 AM - 4:00 PM

Sat & Sun: CLOSED

Mailing Address

P.O. Box 126

107 Industrial Dr.

Fox Lake, WI 53933

Driving Directions

Get In Touch

Phone Number

Email Address

We're Hiring!

Click below for more information

© 2026 | Riverstone Machining | All Rights Reserved

Website Provided By: Web Wisconsin - Digital Marketing & Design